- #Proteus 7 pro license key#

- #Proteus 7 pro software#

- #Proteus 7 pro code#

Education software downloads - Proteus by Labcenter Electronics and many more programs are available for instant and free download.

#Proteus 7 pro license key#

Proteus 7 Professional License Key Download Macĭownload proteus 7 isis professional proteus for free. Thank you for your patience :) and please feel free to point out any errors/give suggestions to improve the circuit. The value on the LCD is updated in real-time, as the current value is changed, by toggling the WR pin of the ADC, and clearing and re-displaying the text after a regular interval of 40 ms (arbitrary low value). Since the output was supposed to be shown only till one decimal place, so a 2-stage division was sufficient. The remainder was taken and multiplied by 10, and a second division was performed to get the value of the first number after the decimal place. In the first stage, the quotient was calculated and sent to display on LCD. So instead the division was performed in 2 stages. Output of 8086 cannot occur in decimal, as data_type float is not supported by 8086. Since 8086 does not support float arithmetic, all the values were converted into whole numbers (truncating decimals to 2 places and mulitplying by 100) and division was performed. So for each change in the binary value, the corresponding ppm value was found out from the following equation: The output from the ADC is in the range of 00H to FFH (0 to 255 in decimal). A simple equation was used to derive the ppm value. The max ppm value that can be shown on the LCD screen was stored in a variable and it can be easily changed without affecting any other part of the program. The main program is at the top followed by all the procedures involved. #Proteus 7 pro code#

The code was written in assembly language in a modular manner.

The LCD display unit LM020L was connected to the port-B of 8255, and remaining control signals required for ADC and LCD display were given by port-C pins PC0, PC1, PC2, PC3. This ADC was controlled by the WR pin with the help of 8255 PPI controller and the output of the ADC was given as input to 8255.Ĩ255 was operated in I/O mode along with port-A as input port while port-B and port-C as output port. This output was fed to the ADC, which is a 1-channel 8 bit ADC. The transconductance of the VCCS was also modified (21 micro Amp/V) to support 105 micro Amp current for the total length of the potentiometer. This current was then passed on to a resistance of value 47.619 kOhm, which comes from the max input voltage to the ADC which is 5V and the max output current of the sensor as 105 micro Amp. The humidity sensor in the above circuit was modelled by a Voltage Controlled Current Source (VCCS) and the voltage was changed by using a potentiometer. Humidity sensor modelled as a VCCS (Voltage Controlled Current Source) along with a potentiometer to change output current 8255 PPI, Humidity output signal processing and LCD display.READ and WRITE Enable for EVEN and ODD Banks of ROM and RAMĨ255 chip select logic (base address of 8255 = 00H)

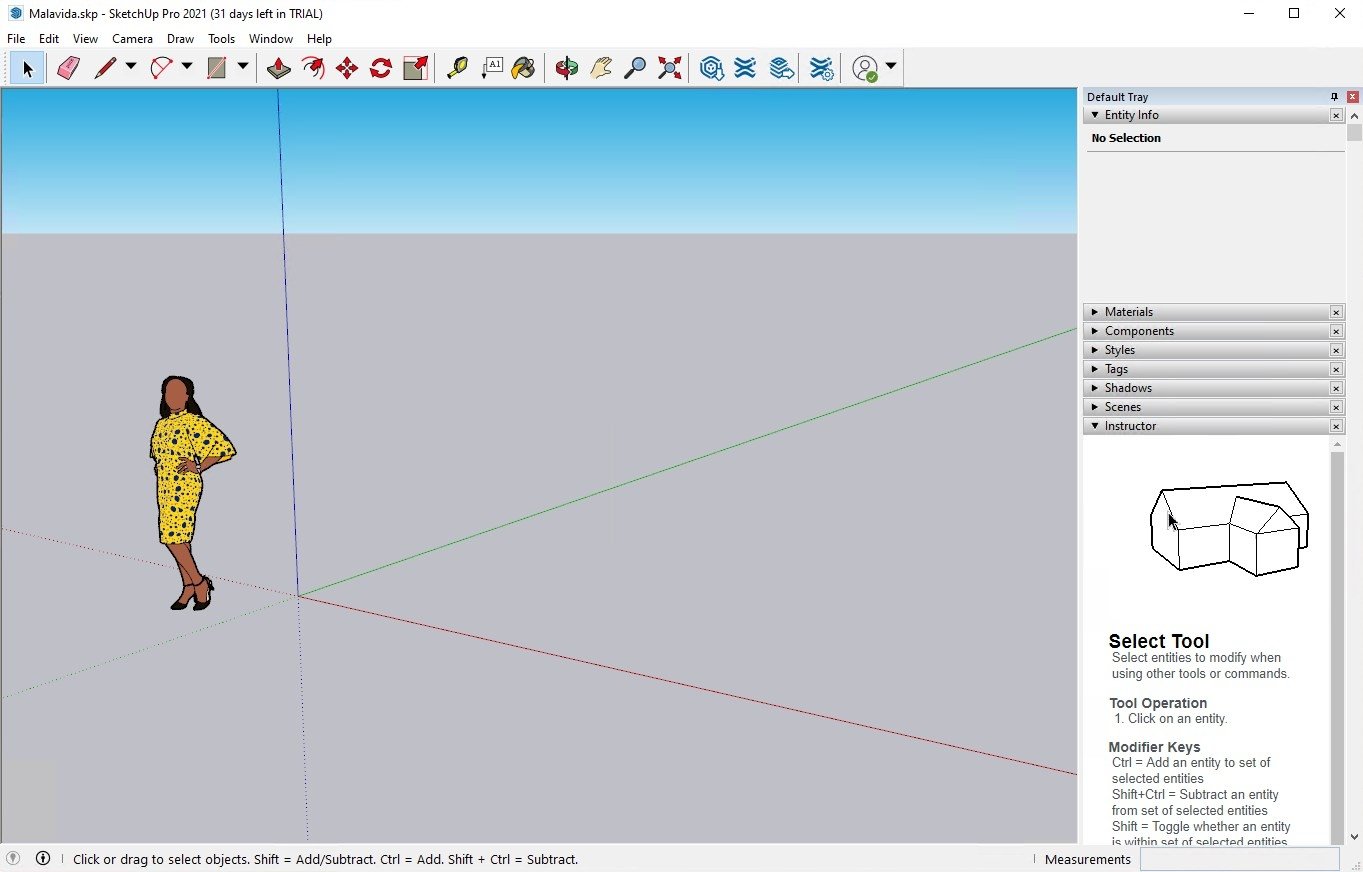

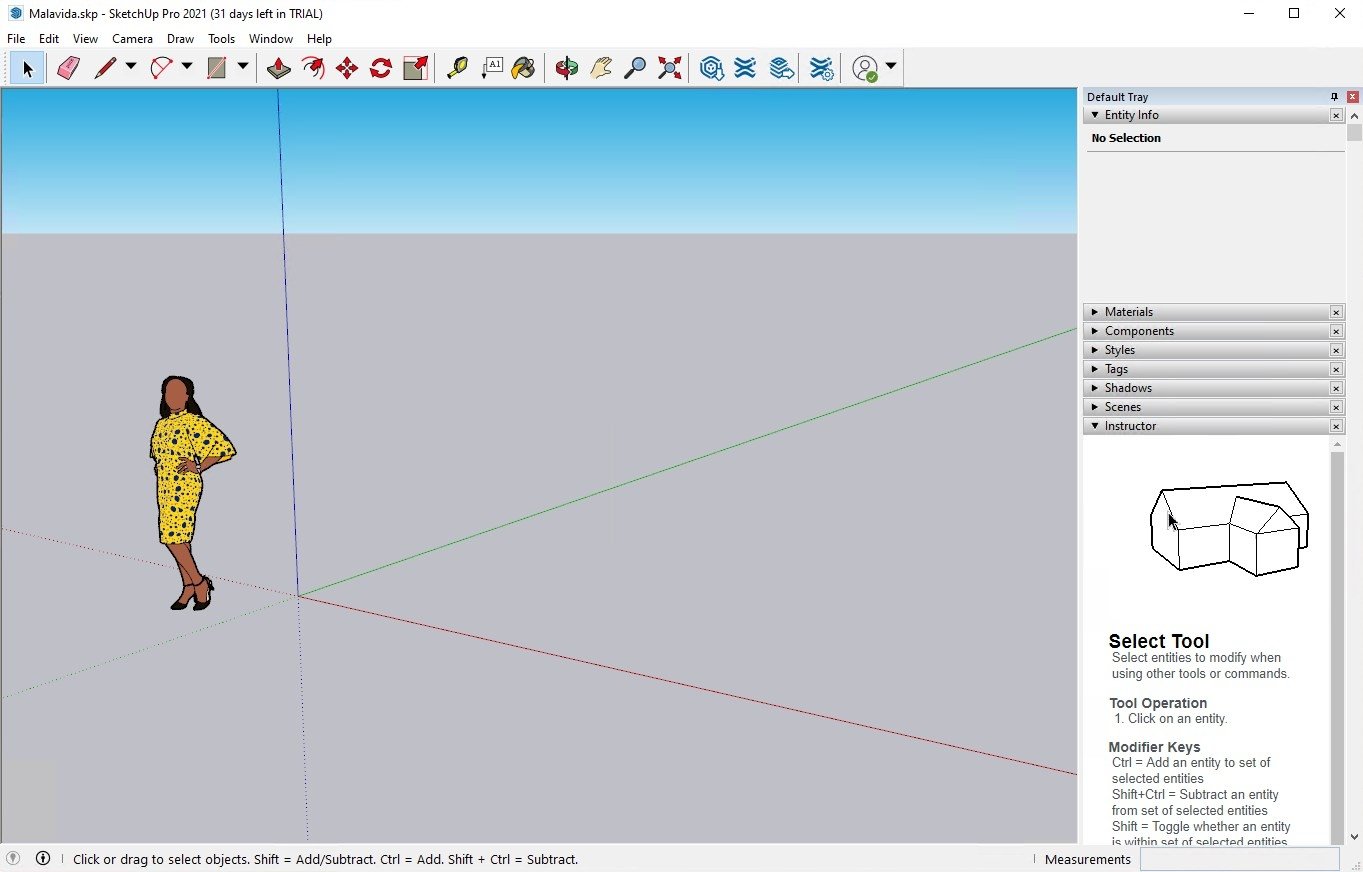

Memory Interfacing along with peripheral I/O Interfacing. 8086 microprocessor interfacing circuit to demultiplex address and data linesħ4LS373 (Octal Latch) for Address de-multiplexingħ4LS245 (8 bit bi-directional buffer) for Data de-multiplexing. The executable file was loaded into the design and the simulation was run.īelow are some of the screen shots of the circuit designed and the humidity output. The code was comipled into an executable file via EMU 8086 application. The circuit was designed in Proteus 7 Professional and the code was written in Assembly Language. The humidity sensor outputs current in micro Amperes and this has to be converted into appropriate ppm values assuming a linear function between current and humidity. This project is focused on displaying the humidity value in ppm (parts per million) from a humidity sensor.

Memory Interfacing along with peripheral I/O Interfacing. 8086 microprocessor interfacing circuit to demultiplex address and data linesħ4LS373 (Octal Latch) for Address de-multiplexingħ4LS245 (8 bit bi-directional buffer) for Data de-multiplexing. The executable file was loaded into the design and the simulation was run.īelow are some of the screen shots of the circuit designed and the humidity output. The code was comipled into an executable file via EMU 8086 application. The circuit was designed in Proteus 7 Professional and the code was written in Assembly Language. The humidity sensor outputs current in micro Amperes and this has to be converted into appropriate ppm values assuming a linear function between current and humidity. This project is focused on displaying the humidity value in ppm (parts per million) from a humidity sensor.

Modelling of 2D-Material based Humidity Sensor - Development of circuit to drive the Humidity Sensor VLSI Design/Circuit Design

0 kommentar(er)

0 kommentar(er)